CHROMA Impulse Winding Tester 19301A

CHROMA Impulse Winding Tester 19301A

CHROMA Impulse Winding Tester 19301A

CHROMA Impulse Winding Tester 19301A

CHROMA Impulse Winding Tester 19301A

CHROMA Impulse Winding Tester 19301A

Sản Phẩm

CHROMA Impulse Winding Tester 19301A

- Giá : Liên hệ

- MASP : 19301A

- Nhà sản xuất : CHROMA

- The 19301A Impulse Winding Tester combined with high/low inductance applied technology has 1000V impulse voltage and a 200MHz high speed sampling rate that satisfies test requirements for a wide range of power inductance products from 0.1uH to 100uH. The built-in Area Size and Differential Area Comparisons, FLUTTER Value and LAPLACIAN Value functions make it an effective way to inspect the coils for poor insulation. The unit analyzes the waveform at high speed with a sophisticated sampling process to successfully detect coils with poor insulation and provides withstand voltage tests on winding and magnetic core quality. The Chroma 19301A can be applied to low inductance winding components test with minimum 0.1uH inductance. The functions provided for low inductance tests include 4-wire test, contact check, inductance check and voltage compensation that avoids voltage errors resulting from the variance of DUT inductance or equivalent wiring inductance. The colorful display and screen capture function enables the user to save waveforms through the USB port on the front panel. The 19031A is suitable for on-site production as well as R&D and quality assurance.

Chi tiết Sản phẩm

Chi tiết Sản phẩm

High Speed Automatic Testing Application

The low inductance applied to smart phones or tablet PCs tends to be slim and light on the appearance. Since fully automatic testing and packing devices are adopted for inductance production, high speed test equipment is needed to maintain high speed production. To fulfill this test application, the Chroma 19301A is equipped with high speed and dual coaxial 4-wire test functions that can reduce the impact of wiring length and work with layer test automation machines to bring greater efficiency to the production line.

SMD Power Choke Test Fixture

The size of a low inductance Power Choke is quite small, and to facilitate the testing for layer short errors, Chroma has developed an SMD Power Choke 4-side test fixture (patent) that works with the 19301a inductance difference voltage compensation to assist the product developer or QA staff in improving the test efficiency.

Key Features:

- Datasheet

- 10V~1000V impulse voltage test, with 0.25V test resolution

- High impulse test sampling rate (200MHz), 10bits

- High/Low inductance test (0.1uH~100uH)

- Inductance contact check function

- Inductance differential voltage compensation function

- Breakdown voltage analysis function

- Low voltage range to increase the sensitivity of waveform analysis (32V/64V/128V/256V/512V/1024V)

- USB port for storing waveform & screen capture

- Multi-language, graphical color display

- Standard LAN, USB, and RS232 interfaces

| Model | Description |

| 19301A | Impulse Winding Tester (Low Inductance) |

| Accessories | |

| A193001 | SMD Choke Test Kit |

| A193002 | 1m Test Wire + Test Clip |

| A193003 | 1m Test Wire + Flat Head Cutting |

| A193004 | 1m Test Cable BNC to BNC (incl. BNC Male Connector *2) |

Measurement Technology

Introduction & Theory Of Impulse Test

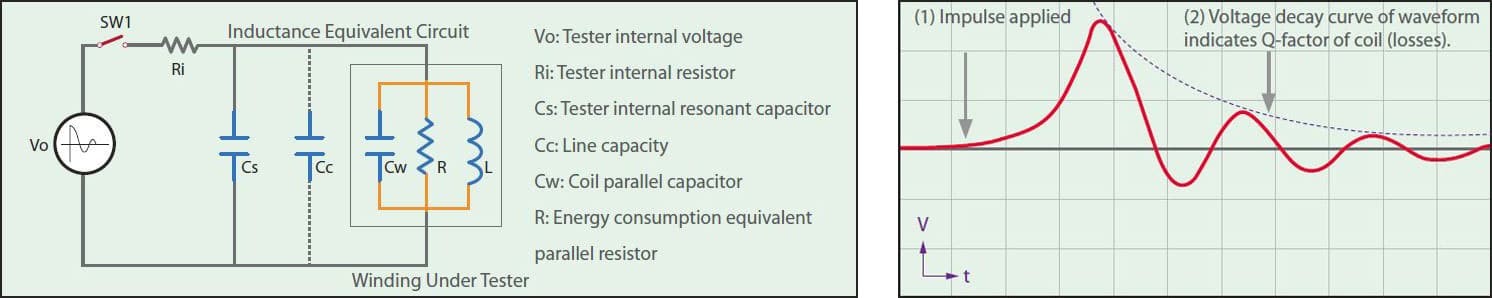

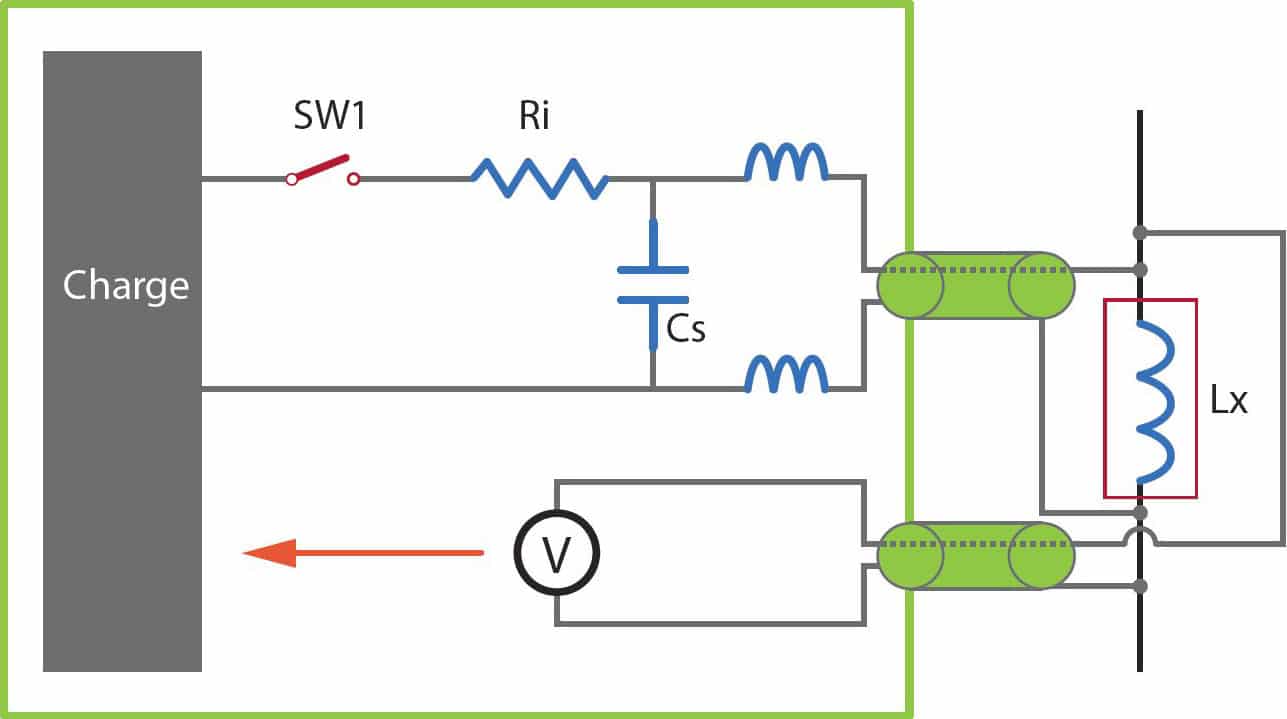

The “Impulse Winding Test” is a “non-destructive” technique that applies a high speed and low voltage pulse to the DUT and adds an impulse voltage on the oscillation capacitor (Cs) of the parallel coil so that the parallel capacitor and coil will generate an LCR oscillation. The oscillation attenuation can be viewed to realize the internal state of the coil including insulation, inductance and parallel capacitance (Cw) (See image: Equivalent Circuit Test Diagram). Next, analyze and compare the equivalent waveform of a good and bad DUT for pass and fail judgment. The function of the impulse winding test is to discover the potential defects – such as a winding layer short, poor electrode welding, and poor internal coil or core insulation, etc. as early as possible.

Equivalent Circuit Test Diagram

4 Waveform Judgment Modes

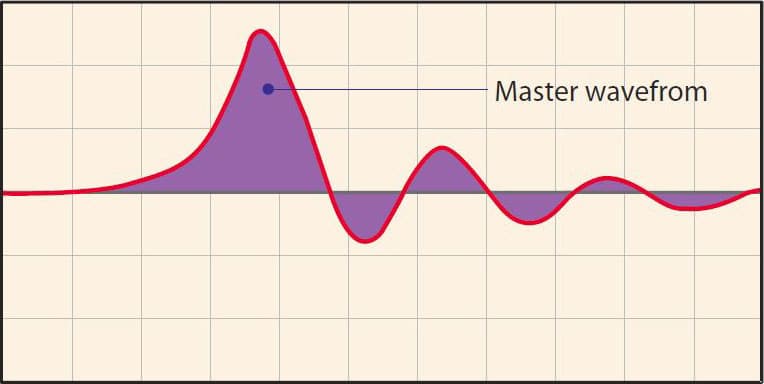

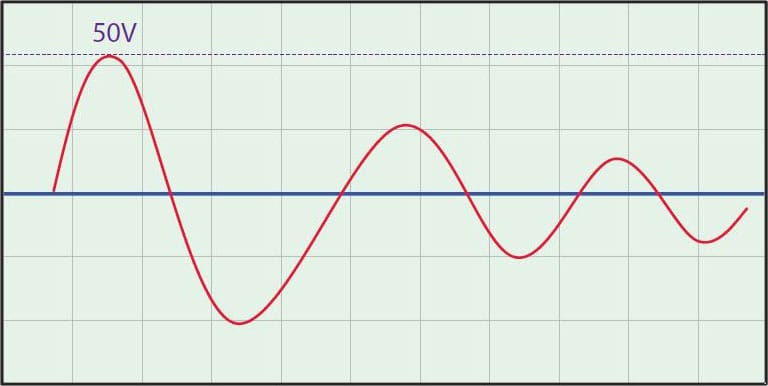

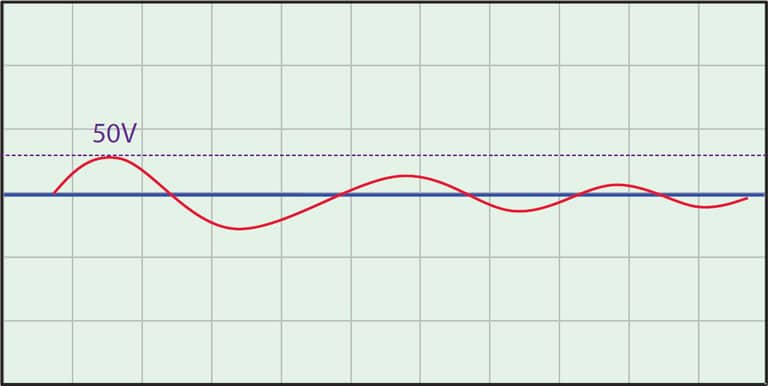

Area Size

This compares each area size of the master coil and the sample coil under test waveforms in the intentionally determined zone.

Area Size

Differential Area

This calculates the area size of the differential portion between the master coil and the sample coil waveforms in the intentionally determined zone.

Differential Size

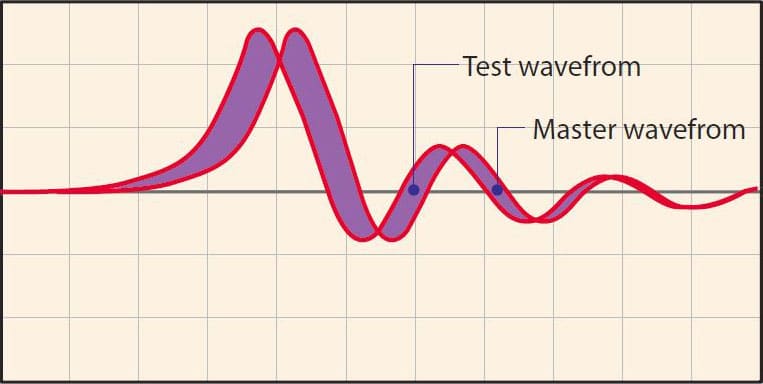

Flutter Value

This test uses the first-order differentiation to calculate the total value. This can effectively detect the waveform over-length caused by the inductance being too low or the presence of electrical discharge.

Laplacian Value

Uses the second-order differentiation to calculate the maximum value. This can effectively detect waveform discontinuity caused by electrical discharge.

Flutter and Laplacian Values

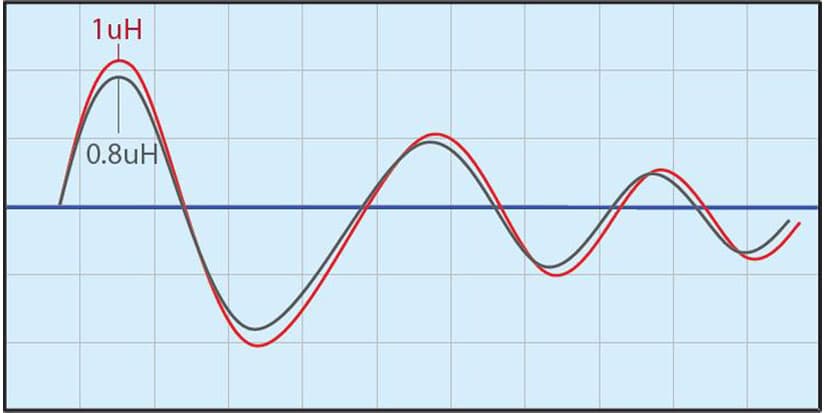

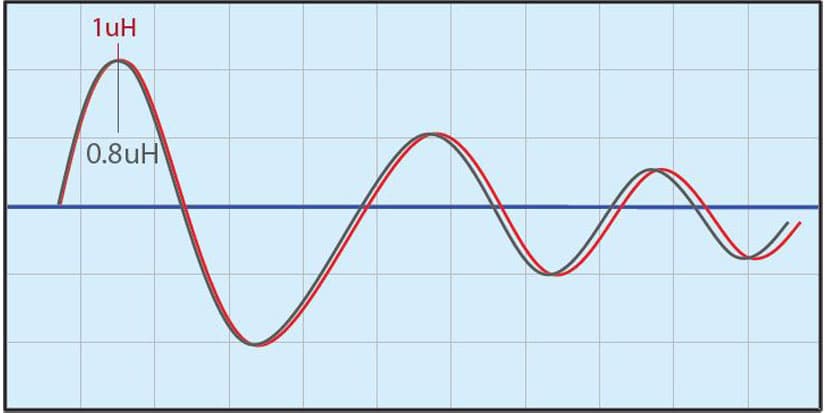

Low Inductance Impulse Test Technology

The Chroma 19301A is specifically developed for testing low inductance winding components. The layer short test for inductance on the products is from 0.1uH to 100uH. The test for a low inductance DUT is different from general products as it is easily affected by the equivalent wiring inductance on the test circuit that makes the test voltage to distribute to wiring and the DUT voltage to become much lower than the set voltage during measurement. Furthermore, the working voltage of a low inductance power choke is used for low voltage, thus the impulse test voltage is normally lower than common inductance products.

Low Voltage Range

Low inductance products, such as the power choke for a smart phone, have a lower working voltage and are smaller in size, making test voltages relatively low. Thus, the impulse test equipment for measuring low inductance requires a low voltage range for waveform analysis. The Chroma 19301A has 6 voltage ranges including 32V, 64V, 128V, 256V, 512V, and 1024V, along with the lowest 0.25V voltage recognition. The minimum test voltage can start from 10V which is capable of increasing the identification of a waveform.

High/Low Inductance Products Testing

Besides low inductance product testing, the Chroma 19301A also covers testing for high inductance products from 0.1uH ~ 100uH. The internal inductance detection function is a very convenient operation that enables the user to learn the amount of DUT inductance, switch to the proper range for testing, and perform comparisons under a proper waveform. A single layer short tester combined with the high/low inductance product testing application not only shortens the time for equipment changes when switching the product line, but also reduces factory facility expenses.

Chroma 19301 Impulse Winding Tester

Common Impulse Winding Tester

4-Wire Test

Since the voltage detection of common 2-wire layer short test device is inside the current loop, the measured voltage is quite different from the DUT for low inductance tests. The Chroma 19301A uses dual coaxial 4-wire detection to significantly improve the voltage accuracy for correct test results.

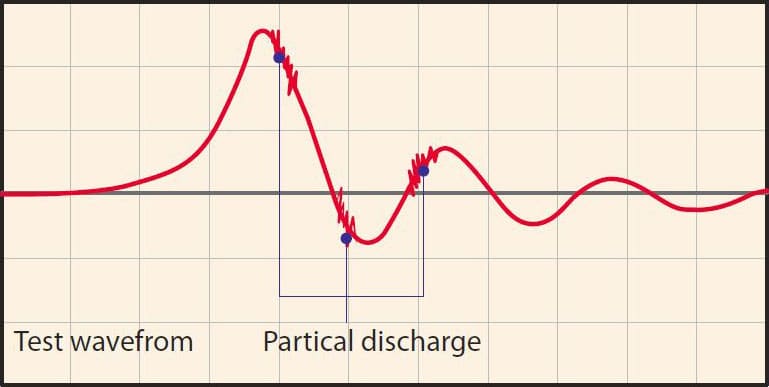

Breakdown Voltage (B.D.V)

The Breakdown Voltage test function of the Chroma 19301A uses the voltage slew rate to detect if the Area Size and Laplacian values are over the set limit value and tests the coil withstand voltage by setting the start/end voltage and the step number. R&D engineers can perform product analysis and research to reduce any weak spots within a coil via this function.

Contact Check (Patent)

To avoid poor contact or open circuit conditions that may make the fixture probe flash due to maximum internal voltage output that may cause damage to the DUT or probe, the Chroma 19301A performs a Contact Check before testing to prolong the probe’s life.

Impulse Winding Tester

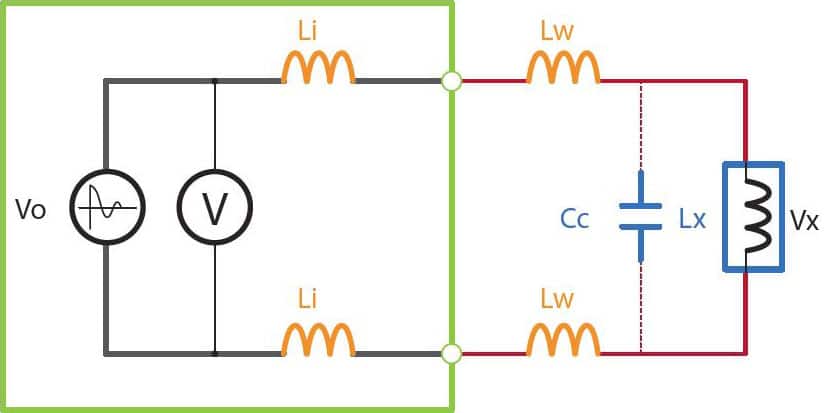

Voltage Compensation (Patent)

Impulse Winding Tester

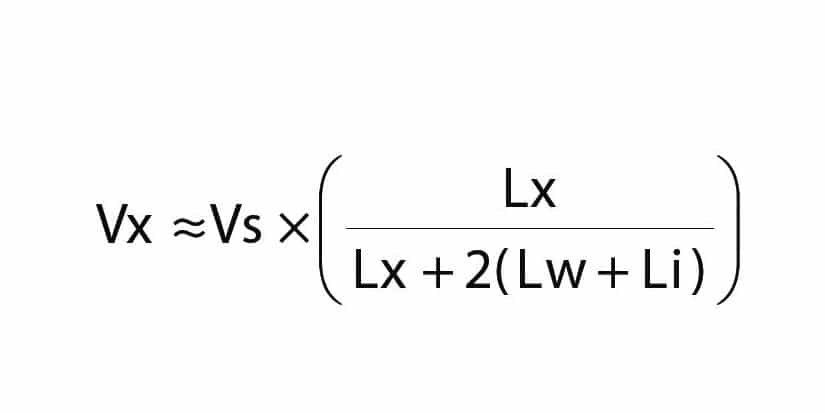

Lx: Inductance DUT

Lw: equivalent wiring inductance

For common applications, the voltage (Vx) of inductance DUT (Lx) on two ends will distribute voltage in series with the wiring inductance (Li&Lw) on the line. The formula used for calculating this is shown above.

Without inductance diff erence voltage

With inductance diff erence voltage