HỆ THỐNG KIỂM TRA CHỨC NĂNG LINH KIỆN PCB

HỆ THỐNG KIỂM TRA CHỨC NĂNG LINH KIỆN PCB

HỆ THỐNG KIỂM TRA CHỨC NĂNG LINH KIỆN PCB

HỆ THỐNG KIỂM TRA CHỨC NĂNG LINH KIỆN PCB

HỆ THỐNG KIỂM TRA CHỨC NĂNG LINH KIỆN PCB

HỆ THỐNG KIỂM TRA CHỨC NĂNG LINH KIỆN PCB

Tin Tức & Dự án

HỆ THỐNG KIỂM TRA CHỨC NĂNG LINH KIỆN PCB

FUNCTIONAL TEST (FCT) - PRODUCT DESCRIPTION :

Functional Test (FCT) is carried out on the assembled PCBs(called PCBA). FCT is the quality control test at the final stage of the production line before shipping the PCBA to the customers. Miniaturization of components and boards makes probing and fixtures difficult. The Low cost PCBA Functional test does not use any probes or fixtures.

The Functional Test Software runs in a external hardware. The external hardware interfaces with the board under test through edge connector. The Functional Test Software accesses each device or component on the board, sends commands to the device, reads and writes to the device to test the functionality.

Our Functional Test software is designed to have a single button and Operator friendly test to detect manufacturing issues. FCT test is low cost and closure to the actual Functionality and Electrical Environment of the board.

FCT ADVANTAGES :

Low Cost Test Strategy - No probes or Fixtures.

Board Powered and Functionality tested.

Edge connectors tested.

Detect manufacturing faults - Open, short, missing components, faulty components.

Debug menu to isolate component/device level issues.

Test Logs Capture and Analysis.

FCT Experiences By Semiki Corp.

Our FCT solutions, be it, pneumatic, toggle clamp, systems integration or burn in, be rest assured that our rich experience allows us to propose solutions for your every scenario.

Here is a gallery of some of our PCBA FCT Fixture solutions that we have provided for our customers.

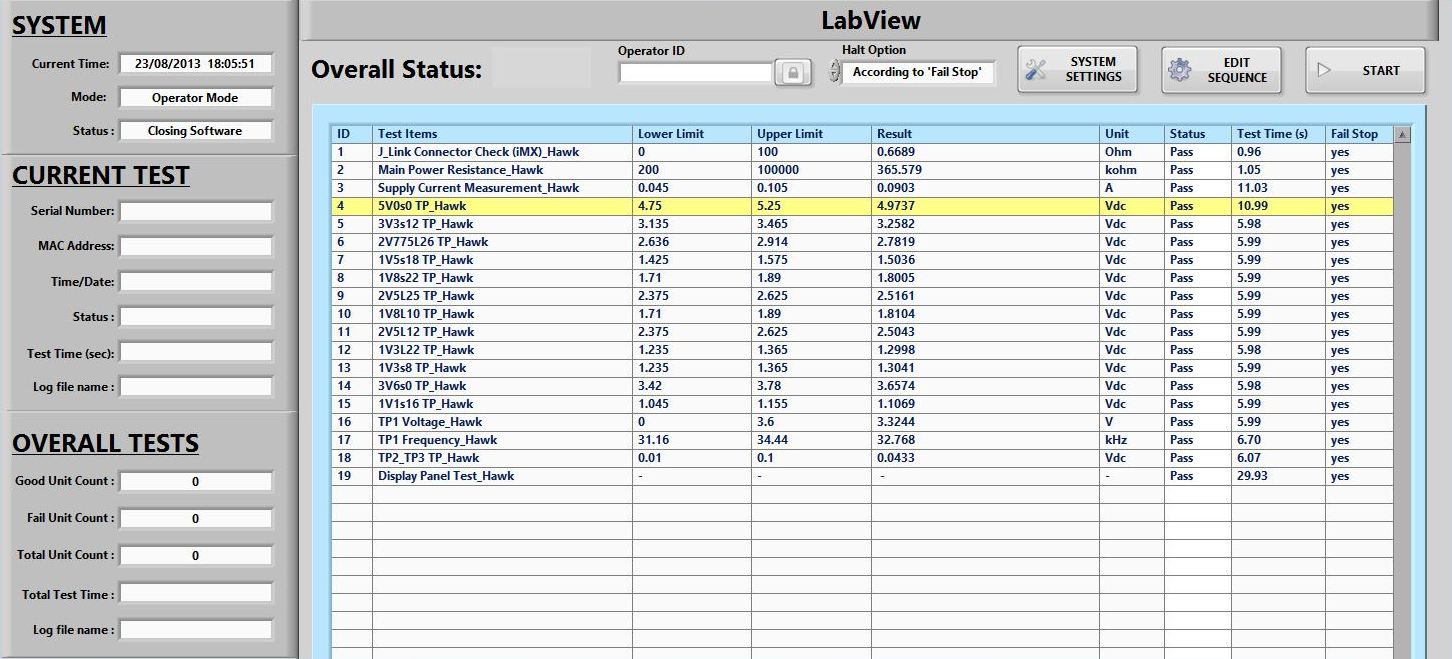

Picture : National Instruments' engineering software LabVIEW Communications System Design Suite,

A design environment designed for rapid deployment of communication systems.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

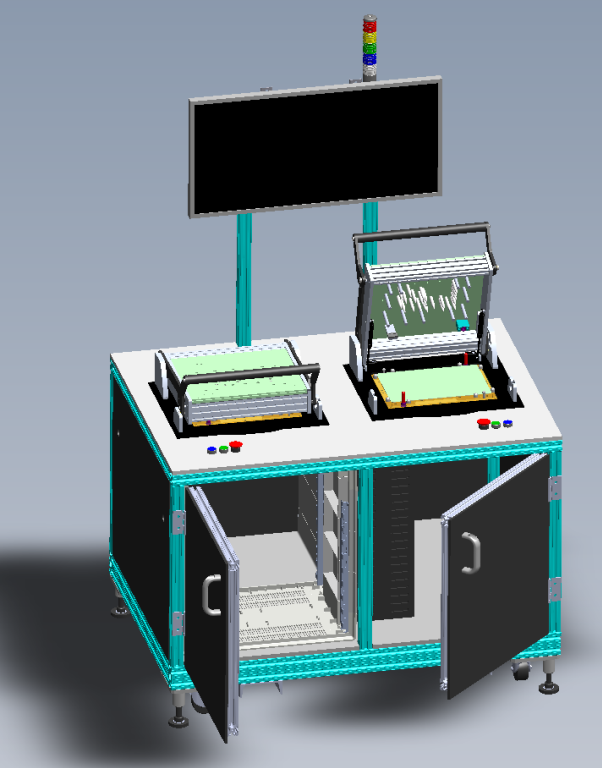

FCT Machine (Functional Circuit Test)

FCT refers to the test method that provides the simulated operating environment to the test target board, so that it can work in designed states to obtain the parameters of each state to verify the function of the UUT.

Generally refers to the functional test of PCBA.

FUNCTIONAL TEST (FCT) - PRODUCT DESCRIPTION :

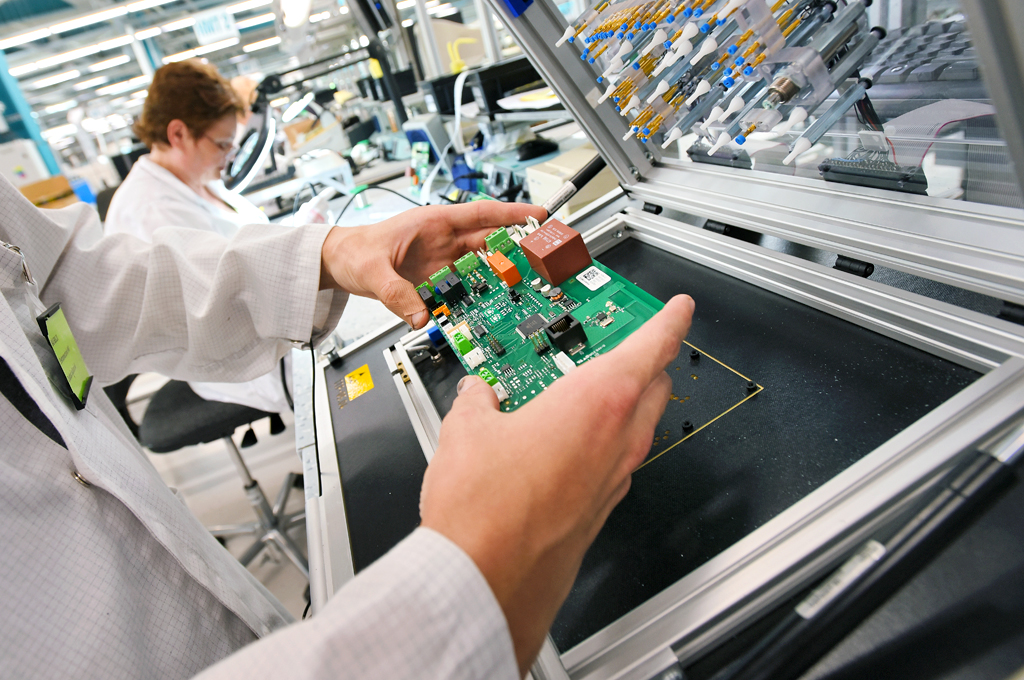

In-circuit and Function Test (ICT/FCT) During in-circuit tests (ICT) all components on the PCB are measured. In doing so, defective components are detected and can be replaced accordingly. Function tests (FCT) check the entire intended function of a PCB. According to the intended area of use, the environment is replicated and the electrical performance of the PCB is checked. In order to optimally fulfill the contacting requirements, various test probes are available. These differ in terms of installation height, grid size (possible distance between probes), tip style, and type of connection – see following illustration. The electrical connection is achieved either with a solder cup or wire-wrap, with or without cable (wireless).

Features :

◆ FCT test fixture is using for testing the functions of the product.

◆ FCT and ICT have similarities but some differences, they are all using for testing the PCB Board.

◆ICT test fixture is mainly using for testing the PCB semi-finished products, and FCT test fixture is using for testing the functions of PCB board that equipped in components.

◆FCT test fixture is a functional test and is mostly professional custom-made. According to the different features of the product to design fixture.

FCT ADVANTAGES :

- Low Cost Test Strategy - No probes or Fixtures.

- Board Powered and Functionality tested.

- Edge connectors tested.

- Detect manufacturing faults - Open, short, missing components, faulty components.

- Debug menu to isolate component/device level issues.

- Test Logs Capture and Analysis

FCT Experiences By Semiki Corp.

Our FCT solutions, be it, pneumatic, toggle clamp, systems integration or burn in, be rest assured that our rich experience allows us to propose solutions for your every scenario.

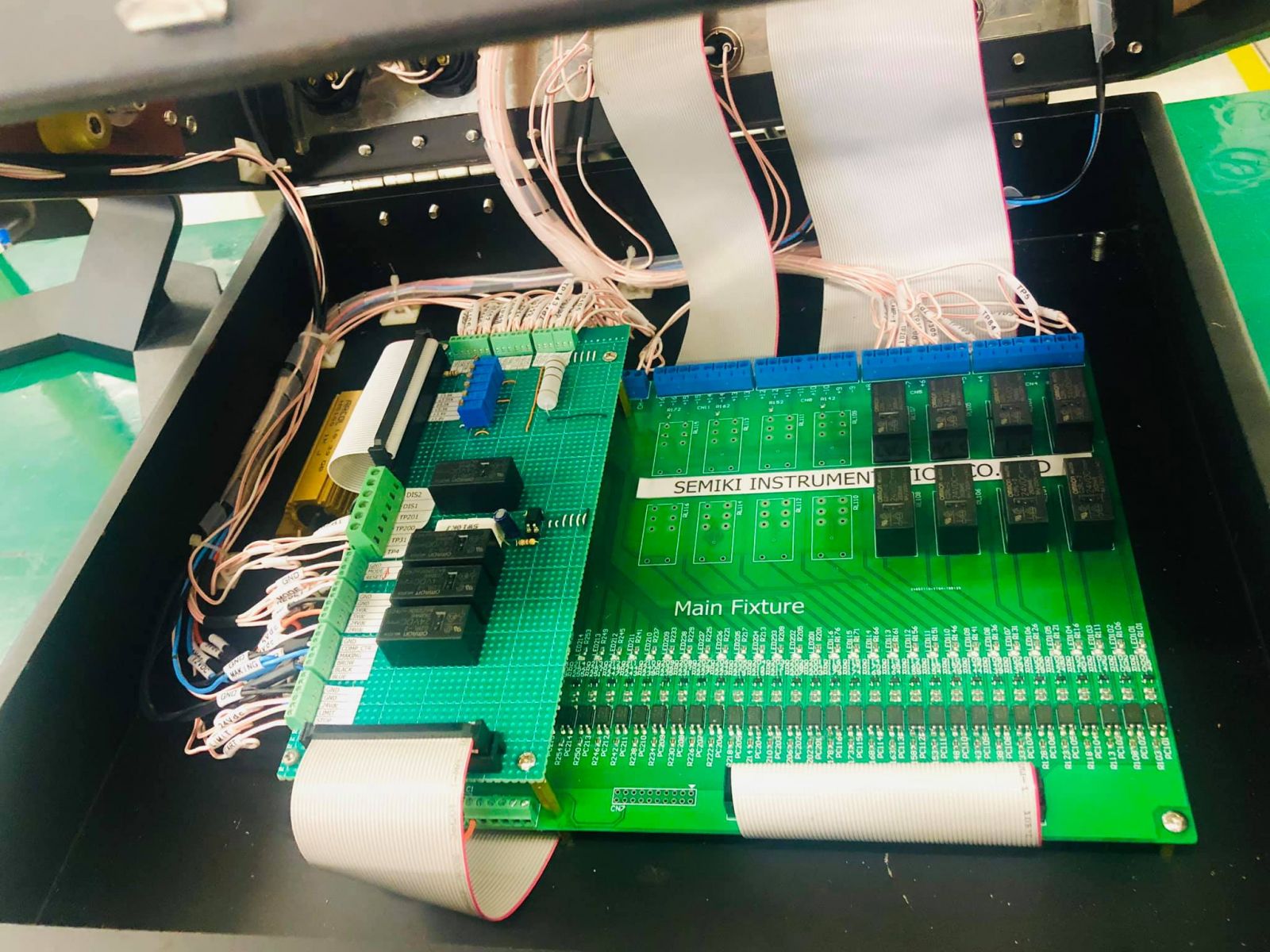

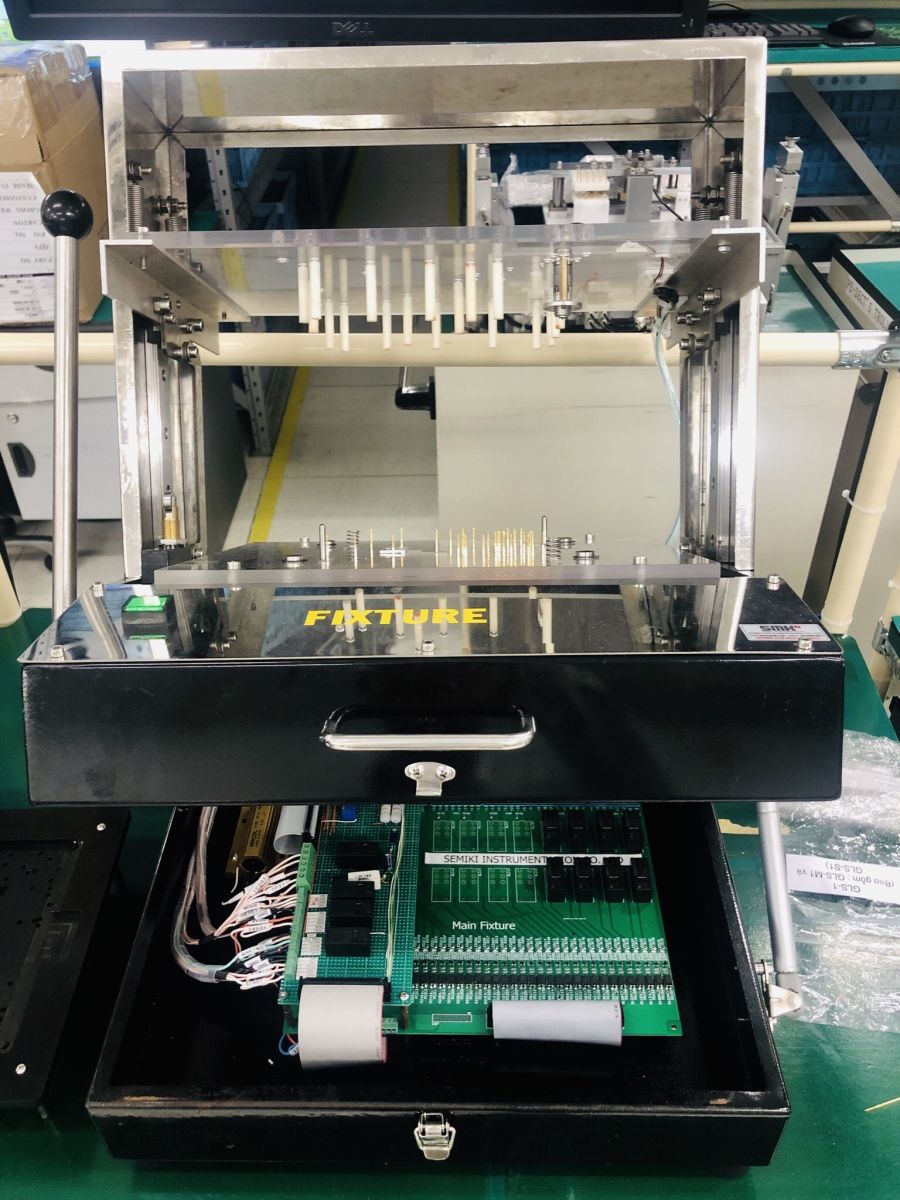

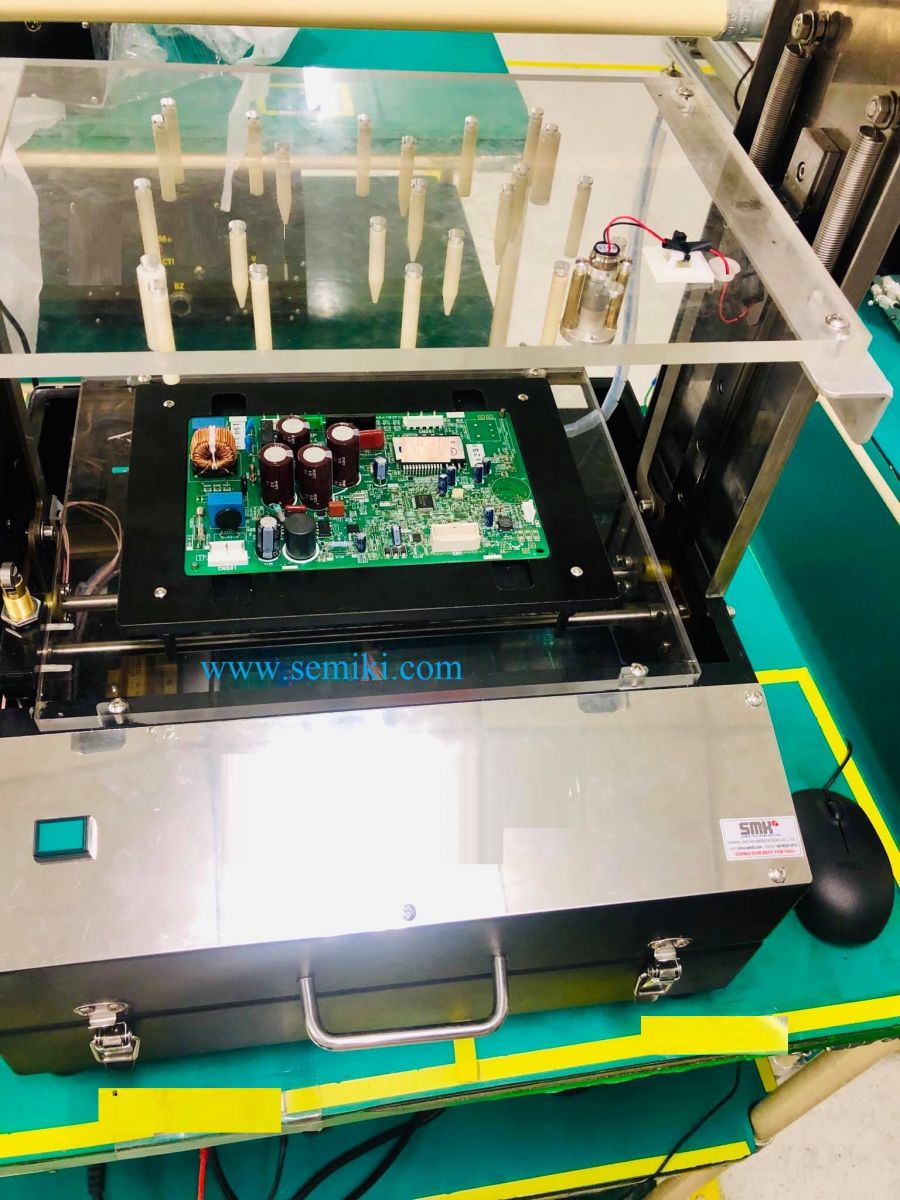

Here is a gallery of some of our PCBA FCT Fixture solutions that we have provided for our customers.

This is one advanced form of testing where functionality of a PCB is tested. In previous tests we have seen so far it deals only with the fabrication and mechanical aspects of a board and detects any defect in it. However this functionality test simulates an Electrical environment for the PCB board under testing and check it’s functional response meets the acceptance criteria. This type of testing is usually carried out by connecting the board via Edge connectors or testing points. An automated machine will run the test on board and process the response received from the board. This type of testing requires special software or firmware for individual types of PCB’s to assess them against criteria such as Electrical response, Feedback, Frequency response and so on.

Functional testing gives an in depth understanding of boards functionality and how it will act in product environment. By this way manufacturers can assess its performance before delivering it to the customer

Picture: Semiki-Export Quality Functional Test Fixtures

SEMIKI provides customized test fixtures for PCB functional testing.

Being in this industry for over 5 years, we have gained the experience and skill to provide fixtures for varied type of applications.

We focus on providing the most efficient , reliable solution to our customers.

Contact :

There are a variety of ways to get in touch with the Precision Measurement Professionals at Semiki Corp.

Please use the contact information on this page : www.semiki.com to get in touch with us.

DISTRIBUTED BY:

Semiki instrumentation Co., Ltd

Email: sales@semiki.com

Office tel: +84 28 2253 3522

~DOING OUR BEST FOR YOU~